Modular Elements and Solenoids

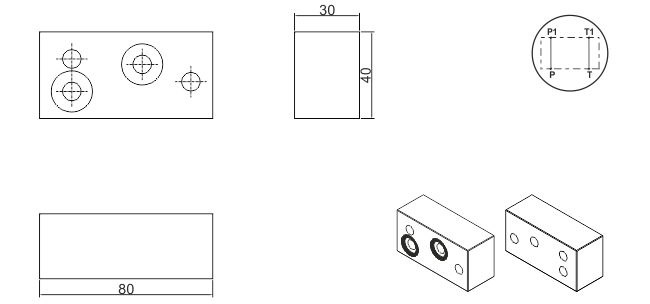

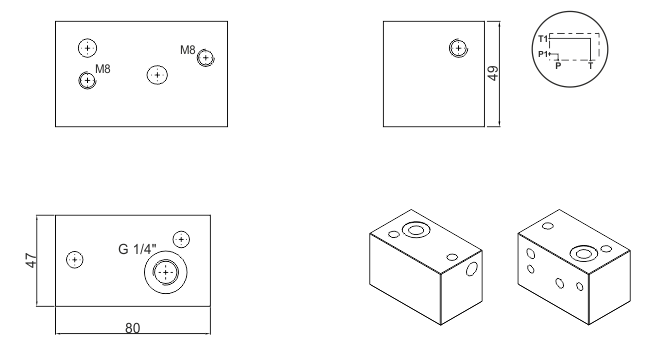

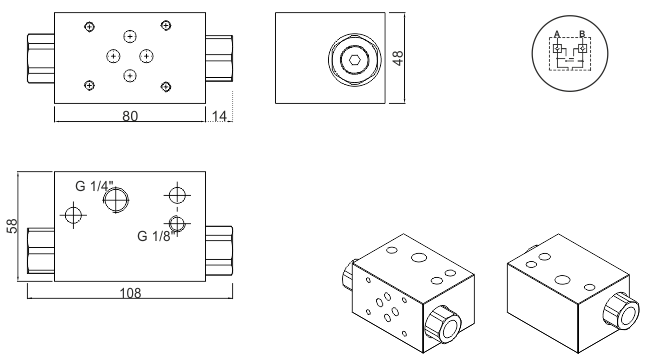

This aluminum block, was thought to be able to space the modular components, by the electric motor mounted on the hydraulic power pack. Its structure allows to fix to the central manifold the blocks of aluminum provided by the circuit, ensuring the right space to avoid collision between the components mounted on the mini power pack. Widely used in mini power packs with three-phase motors.

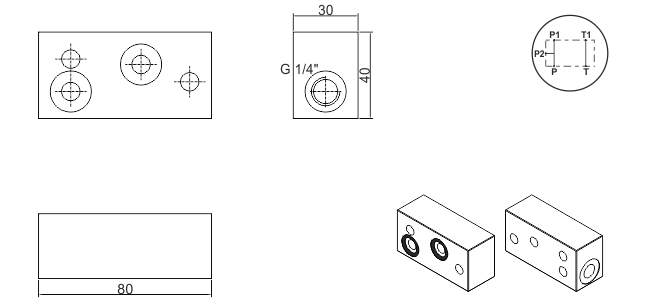

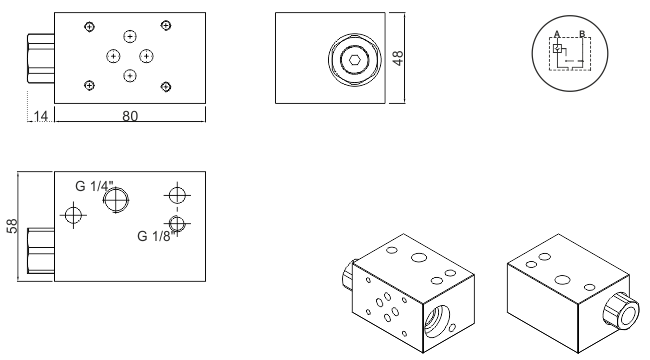

This aluminum block, was thought to be able to space the modular components, by the electric motor mounted on the hydraulic power pack. Its structure allows to fix to the central manifold the blocks of aluminum provided by the circuit, ensuring the right space to avoid collision between the components mounted on the mini power pack. An auxiliary connection is provided on the branch p, used for an eventually intake pressure switch, or for a second intake pressure, connected through a thread 1/4 “gas to the external circuit. Widely used in mini power packs with three-phase motors.

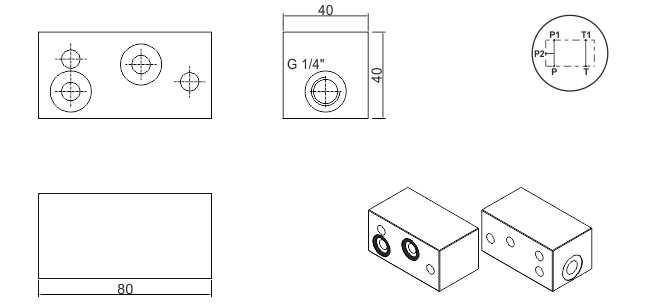

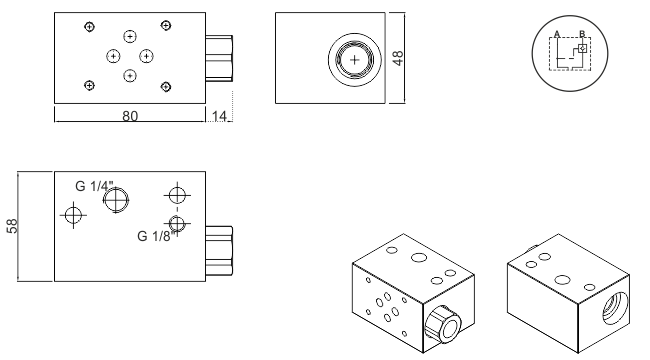

This aluminum block, was thought to be able to space the modular components, by the electric motor mounted on the hydraulic power pack. Indeed it’s essential for manifolds in presence of motor size 112 Its structure allows to fix to the central manifold the blocks of aluminum provided by the circuit, ensuring the right space to avoid collision between the components mounted on the mini power pack. An auxiliary connection is provided on the branch p, used for an eventually intake pressure switch, or for a second intake pressure, connected through a thread 1/4 “gas to the external circuit. Widely used in mini power packs with three-phase motors.

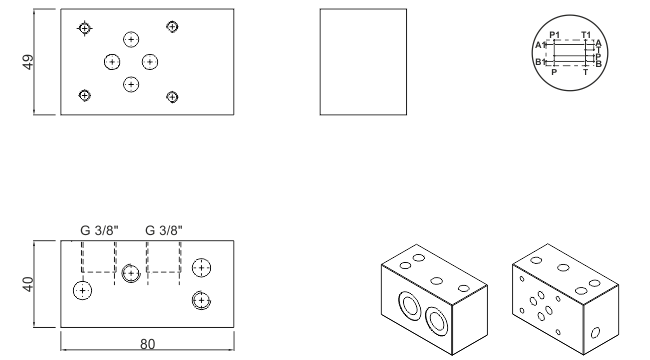

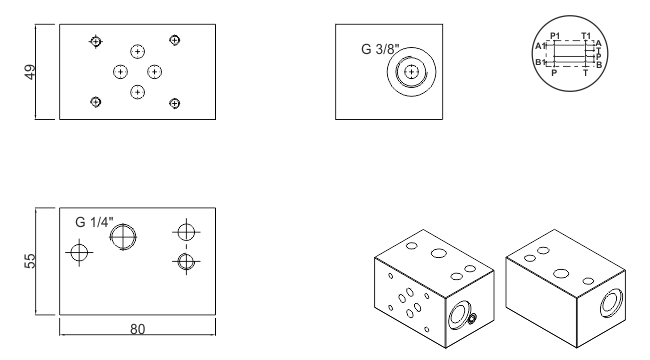

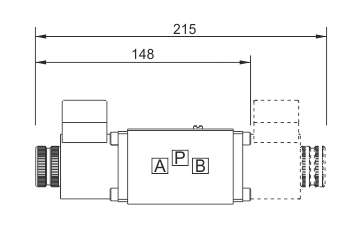

This aluminum block, provides the mounting of solenoid or modular cetop3 valves. The hydraulic outputs 3/8″ gas, give the possibility to use the hydraulic connections in the lower part of the block, reducing the overall dimensions.

The fastening to the central manifold occurs by means of two M8 screws which connect the block to the hydraulic power pack. Is possible to realize the mounting in banks of numerous valve positions, using appropriate screws or bolts for clamping the various modules.

This aluminum block, is designed to have the ability to rotate by 90° the positions of the blocks and the corresponding valves or solenoid valves mounted on them. The advantage of using this block is to limit the overall dimensions of the external components to the central manifold, bringing the possible hydraulic tower modules parallel to the motor.

With the combination of the blocks BL008 and BL010 is possible directing the hydraulic outlets, parallel or lateral relative to the electric motor. The fastening to the central manifold occurs by means of two screws M8 which connect the block to the mini power pack.

This aluminum block, provides the mounting of solenoid or modular cetop3 valves. The hydraulic outputs 3/8″ gas, give the possibility to use the hydraulic connections in the lateral part of the block, reducing the overall dimensions.

The fastening to the central manifold occurs by means of two M8 screws which connect the block to the hydraulic power pack. Is possible to realize the mounting in banks of numerous valve positions, using appropriate screws or bolts for clamping the various modules.

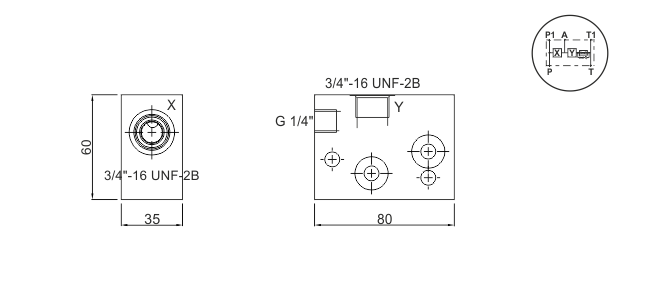

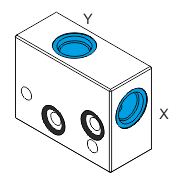

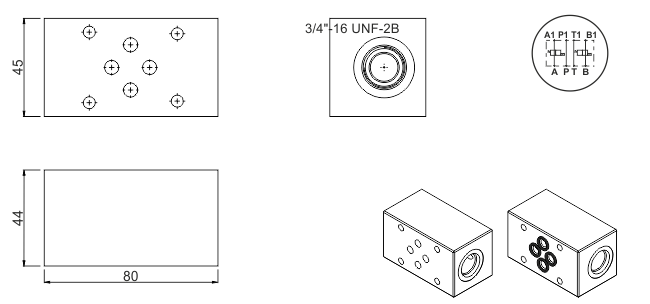

This aluminum block can accommodate two pilotated check valve with 3/4″ 16 UNF 2B thread. In a space equal toa cetop place, has managed to integrate two valves to meet the requirements indicated on the hydraulic diagram. The module thus conceived allows to block the flow of oil between the block and the activator on both branches of the hydraulic connection. The internal pilot valve is ensured by internal ducts made in the same block, with the consequent saving of hydraulic connections. This allows to obtain a clean and extremely compact system. The fastening to the central manifold occurs by means of two screws M8 which connect the block to the mini power pack.

This aluminum block can accommodate one pilotated check valve with 3/4″ 16 UNF 2B thread. In a space equal toa cetop place, has managed to integrate one valve to meet the requirements indicated on the hydraulic diagram. The module thus conceived allows to block the flow of oil on the branch A of the hydraulic connection. The internal pilot valve is ensured by internal ducts made in the same block, with the consequent saving of hydraulic connections. This allows to obtain a clean and extremely compact system. The fastening to the central manifold occurs by means of two screws M8 which connect the block to the mini power pack

This aluminum block can accommodate one pilotated check valve with 3/4″ 16 UNF 2B thread. In a space equal toa cetop place, has managed to integrate one valve to meet the requirements indicated on the hydraulic diagram. The module thus conceived allows to block the flow of oil on the branch B of the hydraulic connection. The internal pilot valve is ensured by internal ducts made in the same block, with the consequent saving of hydraulic connections. This allows to obtain a clean and extremely compact system. The fastening to the central manifold occurs by means of two screws M8 which connect the block to the mini power pack.

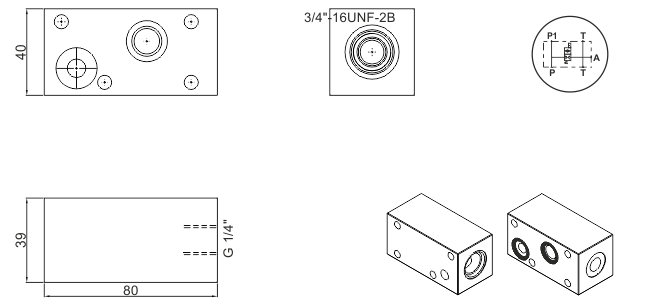

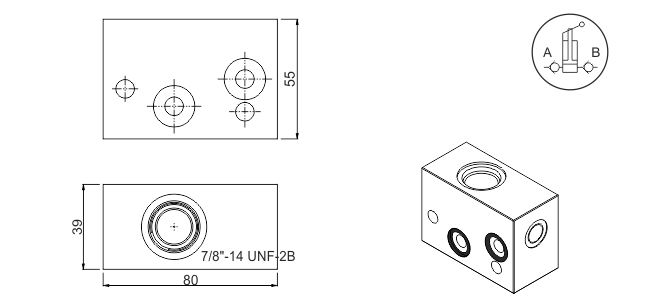

This aluminum block, allows to housing valves and solenoid cartridge valves with 3/4″ 16 UNF 2B thread. The essential advantage of this component is given by the possibility of being able to intercept the P branch and handle it according to the requests of the hydraulic circuit.The dimension of this block has been surrounded to the cartridge valve dimension, maximasing the space, and giving importance to the compactness of the system. The fastening to the central manifold occurs by means of two screws M8 which connect the block to the mini power pack.

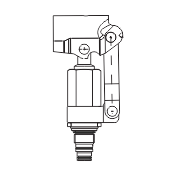

Single and double solenoid valves

Hydraulic scheme

| Code | Scheme | Code | Scheme |

| DM01 | DD01 | ||

| DM02 | DD02 | ||

| DM03 | DD03 | ||

| DM04 | DD04 | ||

| DD05 |

Standard voltages for solenoid valves: 12DC, 24DC, 48DC, 110/50AC, 230/50AC.

Others voltages on request.

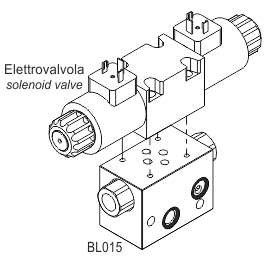

Upon completion of the hydraulic circuit when required, are selected single or double solenoid cetop valves. The choice of the type of solenoid valves, is of particular importance, the proposed range of schemes reflects the most common used in hydraulics. In this case the need of the electric / electronic circuit, the need of the hydraulic circuit, leading to the selection of the correct cetop3. The assembly of these components is facilitated and simplified by the use of the blocks BL008 and BL010. The machining of the mating surface according to ISO between the block and solenoid allows a perfect seal between the modules, through the tightening of only 4 M5 screws