Indispensable particular for the connection between the motor and the central manifold. The range includes four sizes that refer to the relative sizes of the engine: 71, 80, 90, 100. The careful choice of materials, heat treatment and the type of construction allowed us to obtain a series of couplings, that bear high breaking loads. On all outer surfaces of the flanges, were eliminated sharp edges, every corner has been rounded to avoid injury during assembly.

Junction Elements

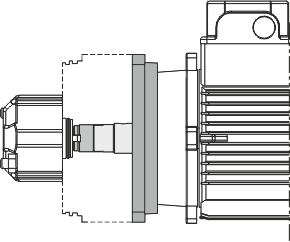

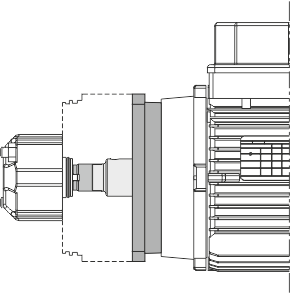

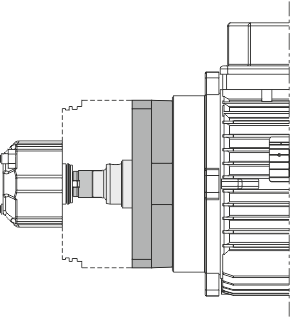

This junction kit between pump and electric motor consists of 3 parts. The pump coupling side (K00), allows to engage the pump shaft, to transmit to this one, the rotary motion generated by the electric motor. The steel was burnished to protect it from oxidation and maintain the integrity of the mechanical characteristics. The mounting system has been simplified, to ensure a kidnapped assembly, and a perfect alignment between the pump shaft and the motor side coupling. The lubrication of the component in correspondence of the joining parts, is recommended to ensure a long life of the whole coupling system: hydraulic pump – electric motor

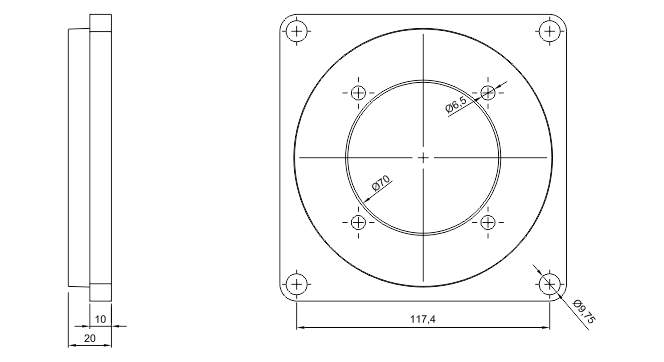

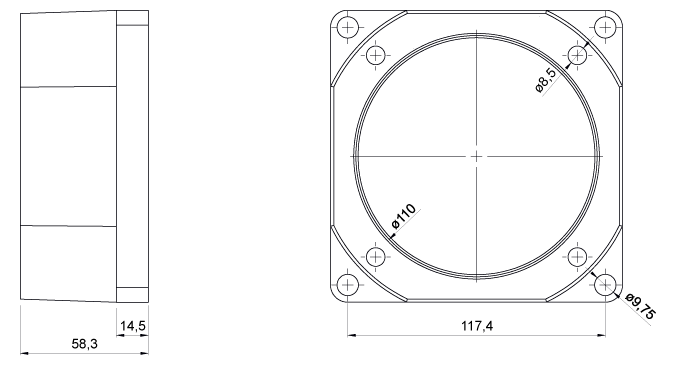

The connection flange between the electric motor and the central manifold, has been realized of cast aluminum. This constructive choice, comes from the need to have a component with ribs, which would ensure excellent mechanical strength and at the same time the maximum value quality – price. All flanges are treated superficially, with an operation of sandblasting, that in addition to eliminating every edge, possible source of injury, also gives it a particularly clear and shiny appearance. The assembly of the flange to the motor, is carried out by tightening of 4 M6 screws, while the fixing on the central manifold, by tightening of 4 M8 screws. With this kind of coupling system, it’s possible to achieve a very fast assembly of the various components, while ensuring a perfect mechanical seal.

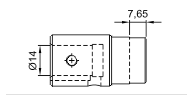

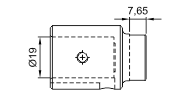

The motor side coupling (K01), allows to engage the motor shaft, with the pump side coupling to transmit to this one, the rotary motion generated by the electric motor. The steel was burnished to protect it from oxidation and maintain the integrity of the mechanical characteristics. The mounting system has been simplified, to ensure a kidnapped assembly, and a perfect alignment between the pump shaft and the motor side coupling. The lubrication of the component in correspondence of the joining parts, is recommended to ensure a long life of the whole coupling system: hydraulic pump – electric motor.

This junction kit between pump and electric motor consists of 3 parts. The pump coupling side (K00), allows to engage the pump shaft, to transmit to this one, the rotary motion generated by the electric motor. The steel was burnished to protect it from oxidation and maintain the integrity of the mechanical characteristics. The mounting system has been simplified, to ensure a kidnapped assembly, and a perfect alignment between the pump shaft and the motor side coupling. The lubrication of the component in correspondence of the joining parts, is recommended to ensure a long life of the whole coupling system: hydraulic pump – electric motor.

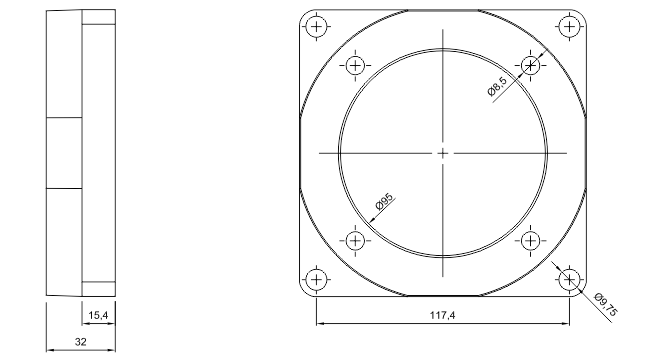

The connection flange between the electric motor and the central manifold, has been realized of cast aluminum. This constructive choice, comes from the need to have a component with ribs, which would ensure excellent mechanical strength and at the same time the maximum value quality – price. All flanges are treated superficially, with an operation of sandblasting, that in addition to eliminating every edge, possible source of injury, also gives it a particularly clear and shiny appearance. The assembly of the flange to the motor, is carried out by tightening of 4 M6 screws, while the fixing on the central manifold, by tightening of 4 M8 screws. With this kind of coupling system, it’s possible to achieve a very fast assembly of the various components, while ensuring a perfect mechanical seal.

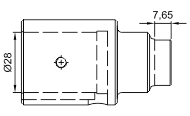

The motor side coupling (K02), allows to engage the motor shaft, with the pump side coupling to transmit to this one, the rotary motion generated by the electric motor. The steel was burnished to protect it from oxidation and maintain the integrity of the mechanical characteristics. The mounting system has been simplified, to ensure a kidnapped assembly, and a perfect alignment between the pump shaft and the motor side coupling. The lubrication of the component in correspondence of the joining parts, is recommended to ensure a long life of the whole coupling system: hydraulic pump – electric motor.

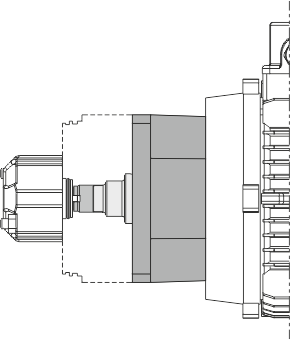

This junction kit between pump and electric motor consists of 3 parts. The pump coupling side (K00), allows to engage the pump shaft, to transmit to this one, the rotary motion generated by the electric motor. The steel was burnished to protect it from oxidation and maintain the integrity of the mechanical characteristics. The mounting system has been simplified, to ensure a kidnapped assembly, and a perfect alignment between the pump shaft and the motor side coupling. The lubrication of the component in correspondence of the joining parts, is recommended to ensure a long life of the whole coupling system: hydraulic pump – electric motor.

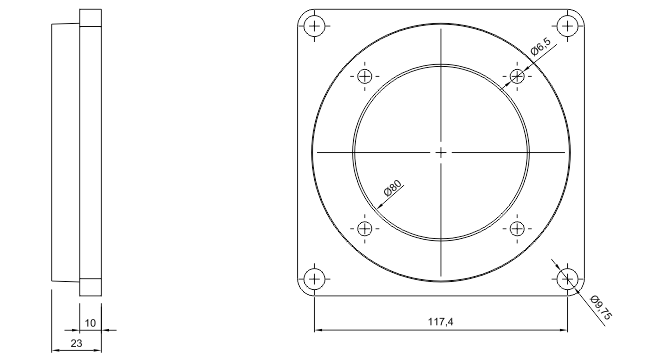

The connection flange between the electric motor and the central manifold, has been realized of cast aluminum. This constructive choice, comes from the need to have a component with ribs, which would ensure excellent mechanical strength and at the same time the maximum value quality – price. All flanges are treated superficially, with an operation of sandblasting, that in addition to eliminating every edge, possible source of injury, also gives it a particularly clear and shiny appearance. The assembly of the flange to the motor, is carried out by tightening of 4 M8 screws, while the fixing on the central manifold, by tightening of 4 M8 screws. With this kind of coupling system, it’s possible to achieve a very fast assembly of the various components, while ensuring a perfect mechanical seal.

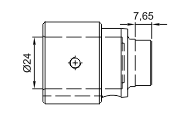

The motor side coupling (K03), allows to engage the shaft, with the pump side coupling to transmit to this one, the rotary motion generated by the electric motor. The steel was burnished to protect it from oxidation and maintain the integrity of the mechanical characteristics. The mounting system has been simplified, to ensure a kidnapped assembly, and a perfect alignment between the pump shaft and the motor side coupling. The lubrication of the component in correspondence of the joining parts, is recommended to ensure a long life of the whole coupling system: hydraulic pump – electric motor.

This junction kit between pump and electric motor consists of 3 parts. The pump coupling side (K00), allows to engage the pump shaft, to transmit to this one, the rotary motion generated by the electric motor. The steel was burnished to protect it from oxidation and maintain the integrity of the mechanical characteristics. The mounting system has been simplified, to ensure a kidnapped assembly, and a perfect alignment between the pump shaft and the motor side coupling. The lubrication of the component in correspondence of the joining parts, is recommended to ensure a long life of the whole coupling system: hydraulic pump – electric motor.

The connection flange between the electric motor and the central manifold, has been realized of cast aluminum. This constructive choice, comes from the need to have a component with ribs, which would ensure excellent mechanical strength and at the same time the maximum value quality – price. All flanges are treated superficially, with an operation of sandblasting, that in addition to eliminating every edge, possible source of injury, also gives it a particularly clear and shiny appearance. The assembly of the flange to the motor, is carried out by tightening of 4 M8 screws, while the fixing on the central manifold, by tightening of 4 M8 screws. With this kind of coupling system, it’s possible to achieve a very fast assembly of the various components, while ensuring a perfect mechanical seal.

The motor side coupling (K04), allows to engage the motor shaft, with the pump side coupling to transmit to this one, the rotary motion generated by the electric motor. The steel was burnished to protect it from oxidation and maintain the integrity of the mechanical characteristics. The mounting system has been simplified, to ensure a kidnapped assembly, and a perfect alignment between the pump shaft and the motor side coupling. The lubrication of the component in correspondence of the joining parts, is recommended to ensure a long life of the whole coupling system: hydraulic pump – electric motor.